Waste Heat Recovery System

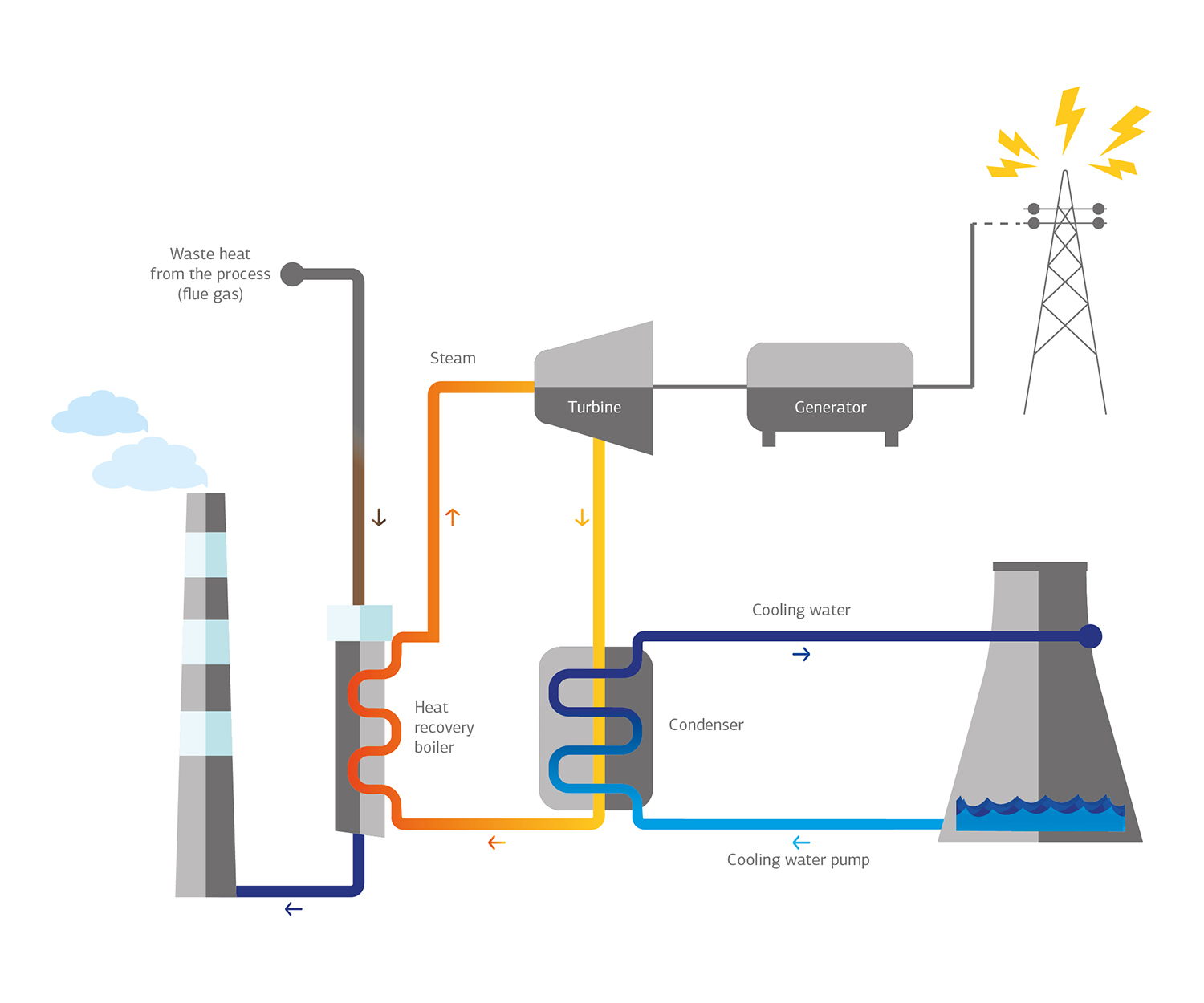

Waste heat recovery system. This waste heat from industrial flue gases can be recovered and recycled. Waste Heat Recovery System Market 2021-2026. Waste Heat Recovery Units WHRU WHRUs are engineered to recover waste heat from the exhaust of gas turbines or reciprocating engines.

Temperature heat recovery a cascade system of waste heat recovery may be practiced to ensure that the maximum amount of heat is recovered at the highest potential. Waste heat recovery systems. Fill out this appraisal form to clarify your heat recovery potential.

Recover exhaust gas waste heat in medium to high temperature applications such as soaking or annealing ovens melting furnaces afterburners gas incinerators radiant tube burners and reheat furnaces. A second boiler situated at the lines preheater will be commissioned in June 2022. In this project the focus was on direct heat recovery by means of heat exchangers.

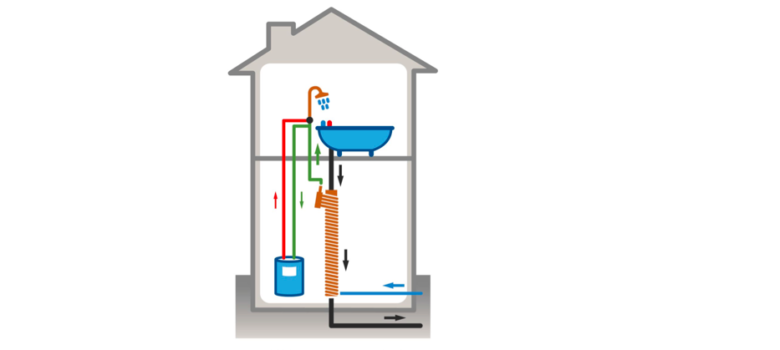

In most cases the optimization of waste heat recovery is done for an. The heating media could be water glycol mixture thermal oil or water depending on the application. In an effort to improve energy efficiency on campus Central Washington University CWU installed a heat exchange system that captures waste heat.

But a waste heat recovery system can recycle those gasses and convert them into electrical energy repeating their use for future operations. About 25 of the total fuel energy. WASTE HEAT RECOVERY SYSTEM 1.

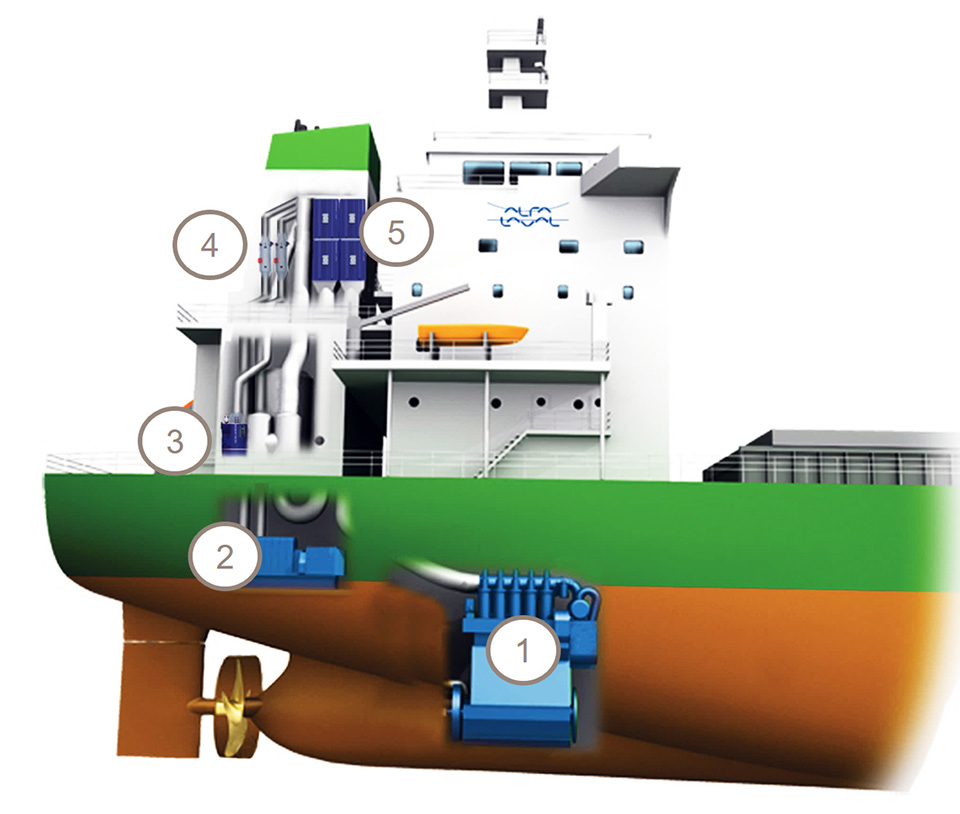

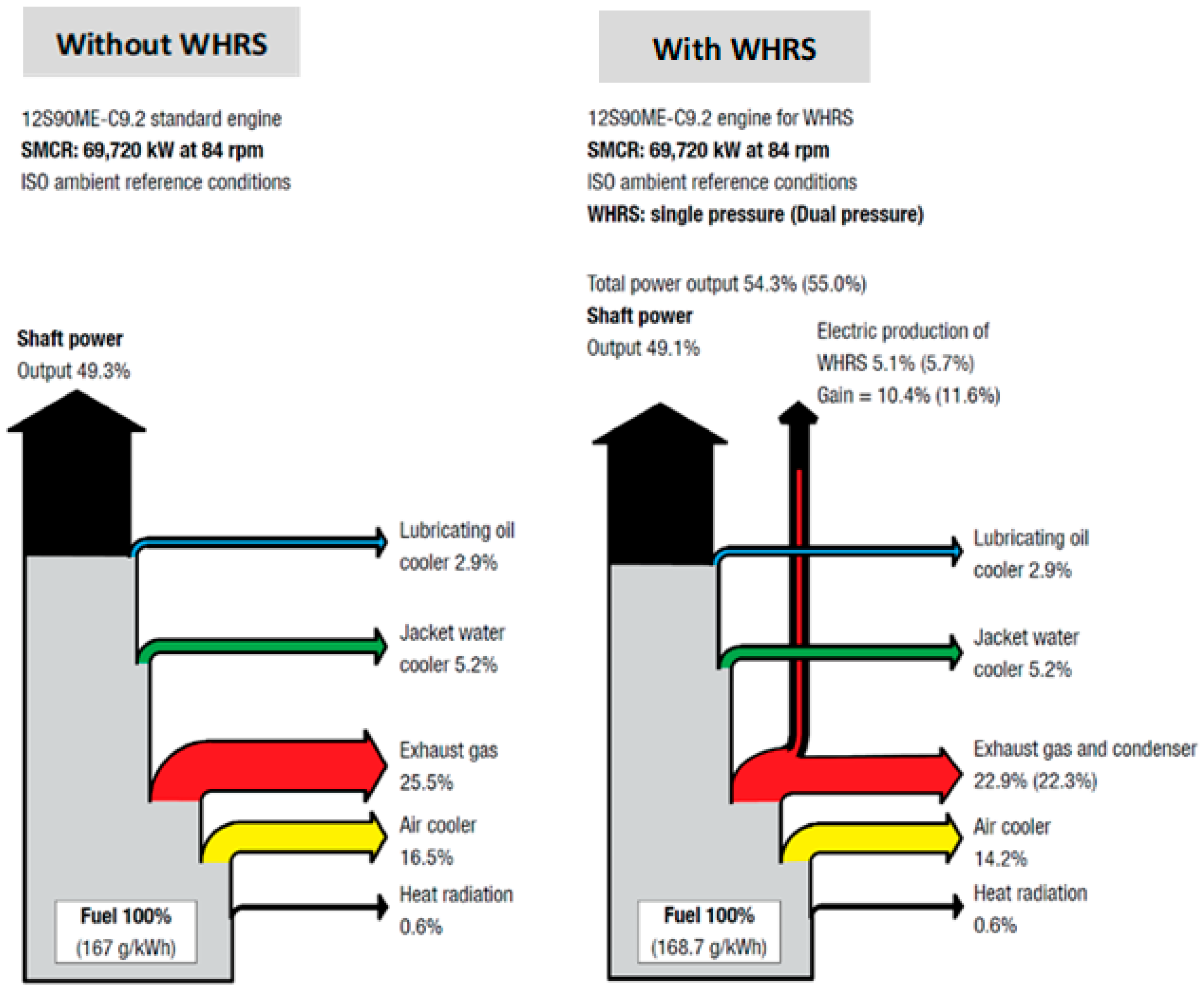

A waste heat recovery system is especially used on an industrial scale with a vast amount of exhaust flue gasses. INTRODUCTION The primary source of waste heat of a main engine is the exhaust gas heat dissipation which accounts for about half of the total waste heat ie. Opel Energy Systems Pvt.

CWUs Waste Heat Recovery System at the Steam Plant. Evolved structures complicate the analysis.

Was established in Nov.

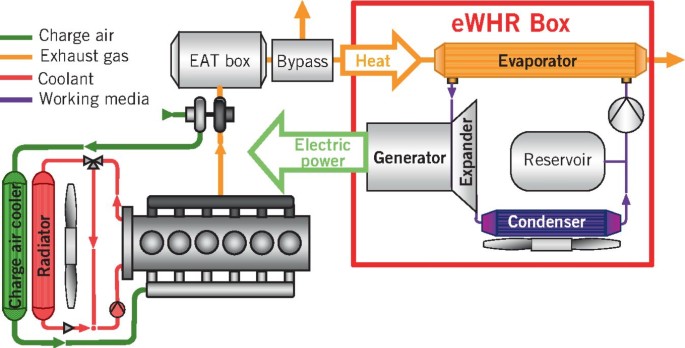

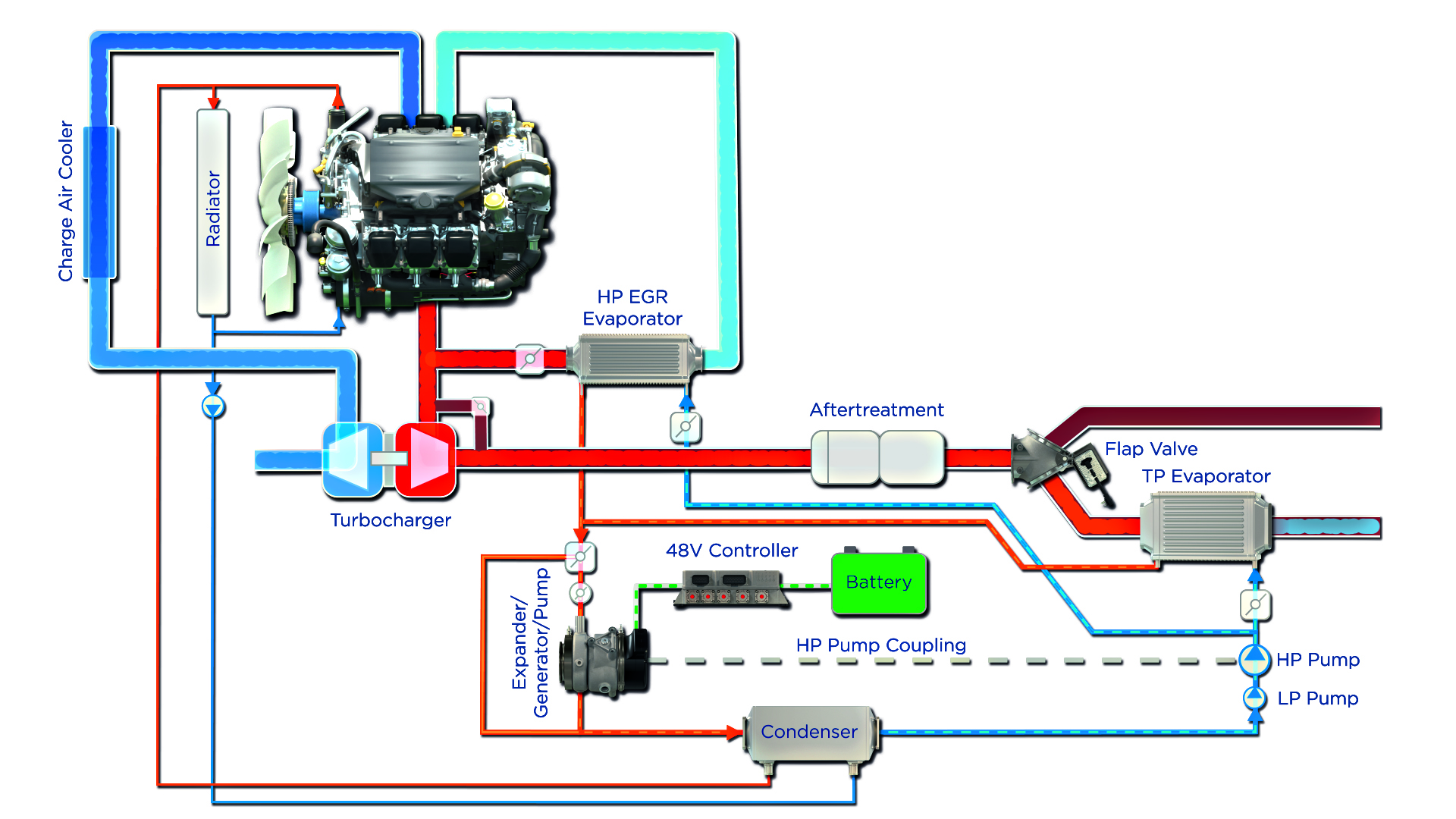

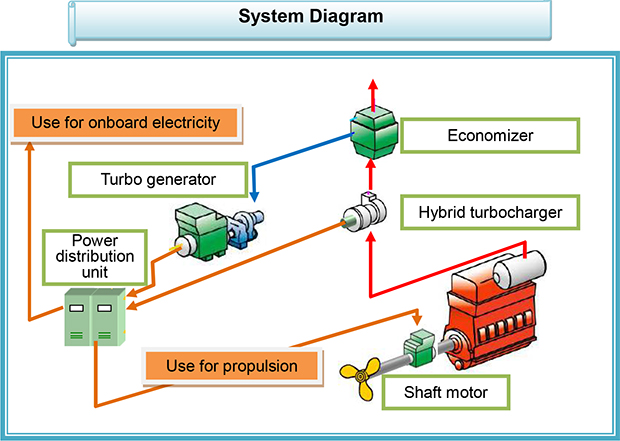

Waste heat recovery systems Waste heat recovery systems recover the thermal energy from the exhaust gas and convert it into electrical energy while the residual heat can further be used for ship services such as hot water and steam. Temperature heat recovery a cascade system of waste heat recovery may be practiced to ensure that the maximum amount of heat is recovered at the highest potential. Was established in Nov. Waste heat recovery systems WHR are put in each category of loss in order to obtain an optimal recovery efficiency. Over 165 installations for the upstream oil and gas segment across diverse locations such as Sakhalin Island. WASTE HEAT RECOVERY SYSTEM 1. Although not technically an engine component or function waste heat recovery systems attempt to regain some of the 50 or so lost thermal efficiency from the fuel used in the engine. Waste Heat Recovery System Market 2021-2026. Waste heat recovery systems are more sophisticated than the simple exhaust gas boiler or economizer and the heat can be used in variety of ways.

System heat recovery ranges in size from 10 MM Btuhr to 300MM Btuhr. System heat recovery ranges in size from 10 MM Btuhr to 300MM Btuhr. Temperature heat recovery a cascade system of waste heat recovery may be practiced to ensure that the maximum amount of heat is recovered at the highest potential. The exhaust gasses can also be used as thermal energy for heating the industrial complex and in combination with a liquid heating solution. Figure 12 Energy flow without waste heat recovery Figure 13 Energy flow with waste heat recovery Fuel Heat generation boilers heaters Process Cooling Surroundings. RDD to advance waste heat recovery technologies. A primary advantage of waste heat recovery is the production of usable heat without any additional fuel expense.

Post a Comment for "Waste Heat Recovery System"